There’s all kinds of specialist glass products out there, but sometimes you just want the best of everything. That’s why we created VLam™ to be the starting point for safety, security, UV protection, noise reduction and – well, anything you want.

VLam™ offers everything you could need in a glass product for your space, as well as range of custom options. The range is a durable, adaptable, high performance glass solution that’s suitable for almost anything you can imagine.

Safety & Security

VLam™ resists penetration from accidental or deliberate impact. If the glass is broken, fragments adhere to the interlayer and are retained in place for safety purposes. Also by thickening the interlayer, VLam™ can be used for protective purposes.

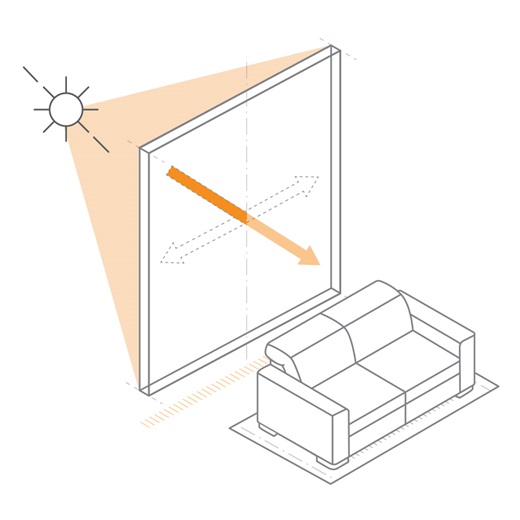

Reduces Risk of Furniture Fading

VLam™ offers high UV protection, reducing the rate of fading for furnishes & finishes.

Minimise Outside Noise

VLam™ provides good noise dampening over the same thickness as usual glass, so you can enjoy a little peace and quiet in your space.

Laminate

VLam™ consists of two or more sheets of glass bonded together by heat and pressure with an interlayer of either PVB, EVA or a specialist high strength ionoplast interlayer.

Tested & Certified

VLam™ is tested and certified to Grade A safety glass standards.

Reduced Rate of UV Fading

The PVB interlayer used in VLam™ eliminates 99% of ultraviolet radiation.

Technical Specifications

- Overhead glazing

- Residential and commercial buildings where safety glass is required

- Please see glass options tab for further information

| Thickness (mm) | Max size (mm) | |||||

|---|---|---|---|---|---|---|

| Product | 6.38 | 6.76 | 8.38 | 10.38 | 12.38 | |

| Clear | ♦ | ♦ | ♦ | ♦ | 5100x3210 | |

| Bronze, Green, Grey | ♦ | ♦ | ♦ | ♦ | 5100x3210 | |

| SuperGreen | ♦ | ♦ | ♦ | ♦ | 4600 x 3210 | |

| Translucent | ♦ | ♦ | ♦ | ♦ | 4280 x 2760 | |

| Translucent Grey | ♦ | 3660 x 2440 | ||||

| Cool Blue | ♦ |

♦ | ♦ | ♦ | 3660 x 2440 | |

| SuperClear | ♦ |

♦ | 3660 x 2440 | |||

The standard PVB interlayer is 0.38mm thick. Also available are 0.76mm and 1.52mm for increased resistance to penetration and security applications.

Glass selection, glazing and manufacturing must be in accordance with Australian and New Zealand Standards

Interlayer colours are based on but are not identical to 6mm Viridian VFloat™ glass colours. The glazing system must allow for water drainage or be completely watertight.

Certain sealants may cause edge de-lamination such as linseed oil putty - neutral cure silicone sealants are recommended.

Laminated glass edges left exposed are not recommended.

Need some advice?

Contact Us